Cross linked hyaluronic acid powder

Bouliga

3913900090

Bouliga

230mda

1kg/bag

| molecular weight: | |

|---|---|

| Availability: | |

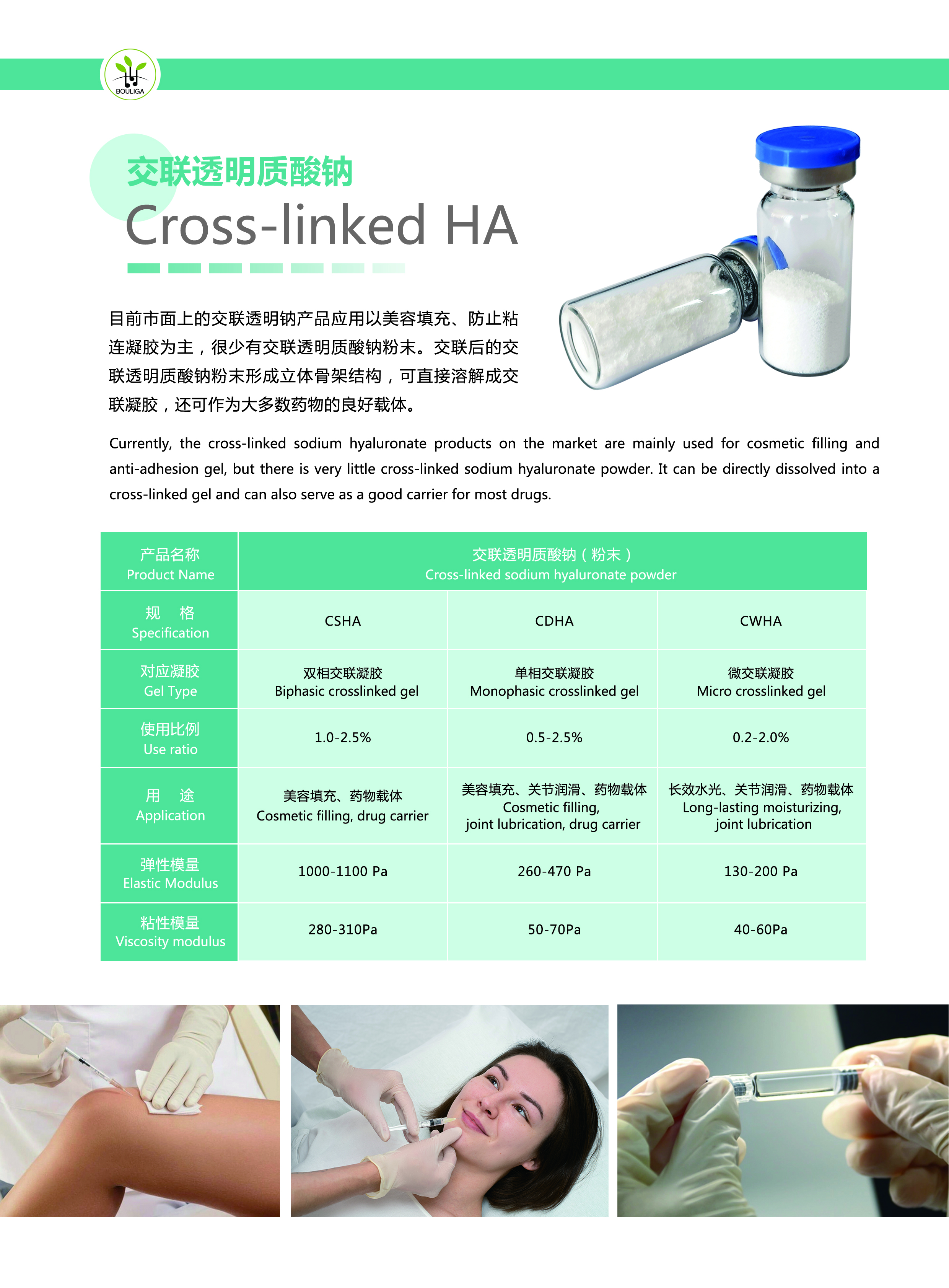

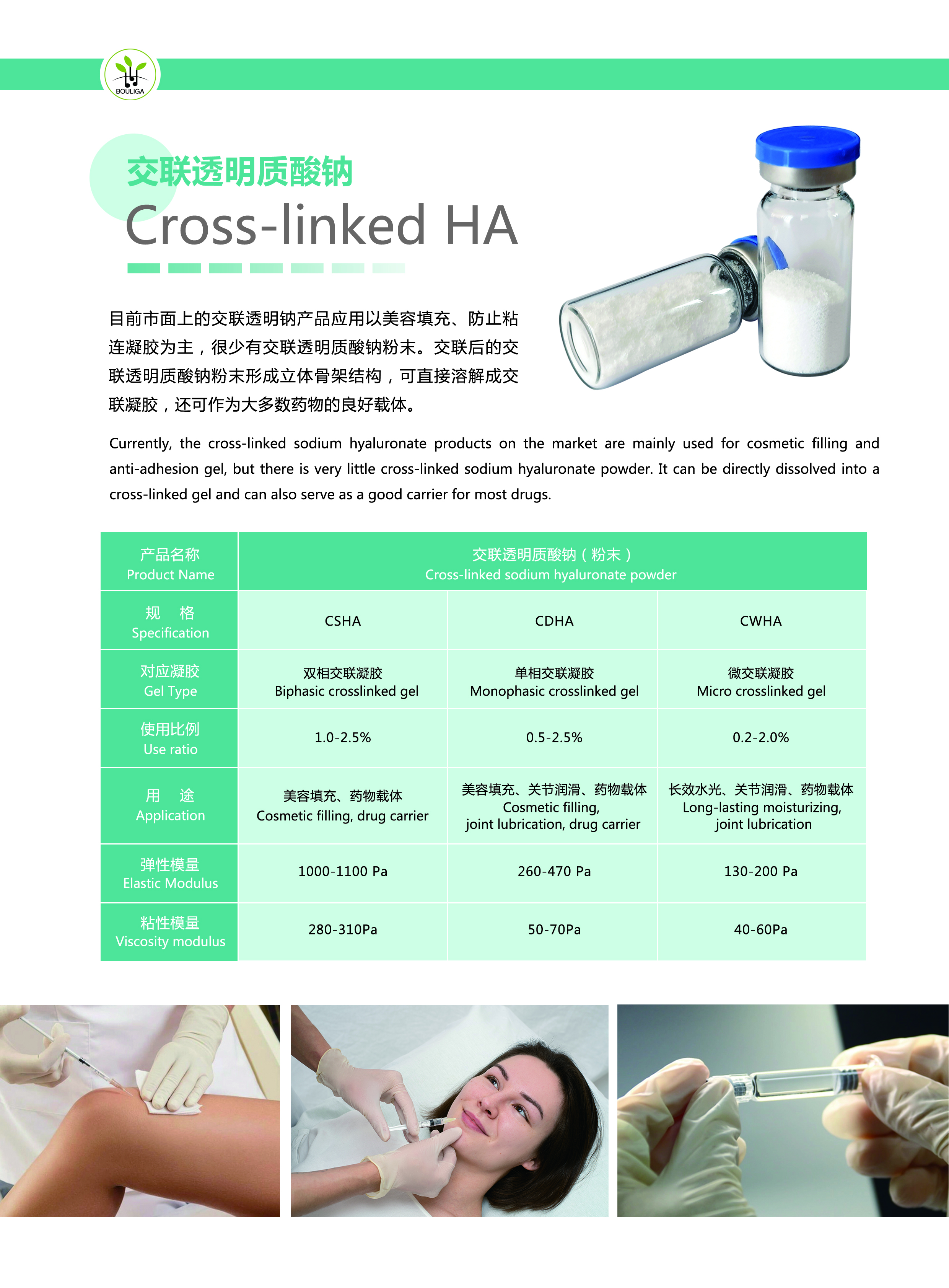

Bouliga’s Cross-linked Sodium Hyaluronate Powder (2.3Mda) is a cutting-edge chemically modified biomaterial designed for high-demand applications in medical aesthetics and pharmaceuticals. Crafted by covalently bonding linear hyaluronic acid (HA) chains via advanced cross-linking agents, this 2.3Mda HA Powder delivers unparalleled stability, viscoelasticity, and in-vivo retention—addressing the core needs of manufacturers for reliable dermal filler raw materials and medical-grade HA solutions. Unlike unmodified HA, the cross-linked polymer structure resists enzymatic degradation, ensuring long-lasting efficacy in clinical settings. Widely trusted by biotech companies and medical device manufacturers, this product excels as an injectable filler base (for lip augmentation, nasolabial fold correction) and a key component in joint cavity injections, ophthalmic viscosurgical devices, and wound dressings. Every batch adheres to strict international standards, making it a top choice for professionals prioritizing safety and performance.

Test Items | Acceptance Criteria | Test Result |

1. Characters | Whiteor almost white granule, powder or fibrous aggregate | Complied |

2. Identification | ||

A. Identification or IR spectrum | Corresponding to reference spectrum | Complied |

B. Uronic acid reaction | Purple and red color | Complied |

3. Clarity and color of solution | Clear;A600nm≤0.01 | Clear;A600nm:0.006 |

4. pH | 5.0~8.5 | 6.3 |

5. Particle size | D10-D90:100~1200μm, D50: Actual value | 210~781μm 445 μm |

6. Viscoelasticity | Actual value | Elastic modulus: 1101.0 Pa Viscous modulus: 311.8 Pa |

7. Loss on drying | ≤15.0% | 2.1 % |

8. Heavy metals | ≤10 ppm | <10 ppm |

9. Residue on lgnition | ≤18.0 % | 11.4 % |

10.Residual ethanol | ≤0.5 % | 0.3 % |

11.Residual BDDE | ≤50μg/g | Not detected |

12.Assay of Sodium Hyaluronate | 95.0 %~105.0% | 95.8 % |

13.Bacterial Endotoxins | <0.05 EU/mg | <0.05 EU/mg |

14.Total aerobic microbial count | ≤500 cfu/g | <20 cfu/g |

15. Total yeasts and molds count | ≤100 cfu/g | <20 cfu/g |

16. Staphylococcus aureus | Negative | Negative |

17.Escherichia coli | Negative | Negative |

18.Pseudomonas aeruginosa | Negative | Negative |

Exceptional Tissue Compatibility: The cross-linked polymer boasts superior biocompatibility, minimizing adverse reactions in medical applications. It integrates seamlessly with human tissue, making it ideal for injectable medical aesthetics and surgical devices.

Rigorous Safety Compliance: Test results confirm undetectable residual BDDE (a common cross-linking agent impurity), heavy metals <10 ppm, and bacterial endotoxins <0.05 EU/mg. This exceeds global medical standards, ensuring patient safety.

Superior Stability & Viscoelasticity: With an elastic modulus of 1101.0 Pa and viscous modulus of 311.8 Pa, the powder maintains structural integrity in vivo, outperforming non-cross-linked alternatives for long-lasting dermal fillers and joint injections.

Controlled Drug Release Support: In pharmaceutical formulations, the polymer precisely regulates drug release rates, boosting therapeutic efficacy and improving patient experience— a critical advantage for drug sustained-release systems.

Patented Cross-linking Technology: Bouliga’s proprietary process ensures consistent molecular weight (2.3Mda) and cross-linking density, eliminating batch-to-batch variations that plague lower-quality HA powders.

Versatile Application Scope: From skin regeneration materials to ophthalmic devices, this powder adapts to diverse manufacturing needs, reducing the need for multiple raw material suppliers.

Packaging Options: 1kg/bag double aluminum foil bags or vacuum packaging with desiccants (moisture-proof, light-resistant). Custom packaging (5kg/bag, 25kg/drum) available for large orders.

Minimum Order Quantity (MOQ): 1kg (sample orders available for qualification testing).

Lead Time: 3-5 working days for standard orders; 7-10 days for customized packaging.

Transportation: Room temperature shipping via TNT, FedEx, DHL, or EMS. Global distribution network ensures timely delivery to over 50 countries.

Storage Conditions: Sealed, dry, and cool environment (2-25°C), protected from direct sunlight. Shelf life: 24 months when stored as recommended.

Simply mix the Cross-linked Sodium Hyaluronate Powder with purified water (ratio depends on desired viscosity; typical 1-5% w/v). Stir gently at room temperature until fully dissolved—no heating required. The solution forms a smooth, viscoelastic gel ideal for injectable fillers.

Yes. The powder holds code 3913900090 and meets CE, FDA, and ISO 13485 requirements for medical devices and pharmaceutical raw materials. Third-party certification reports are available upon request.

Absolutely. The cross-linked polymer forms a breathable protective film, accelerating wound healing and reducing scar formation— a key benefit for medical wound care materials.

Cross-linked HA offers significantly higher stability, viscoelasticity, and in-vivo retention. Non-cross-linked HA degrades quickly, making it unsuitable for long-lasting applications like dermal fillers or joint injections.

Yes. Our team of biotech experts provides free formulation guidance to help optimize your product’s performance. Contact our technical support team for customized solutions.

Bouliga’s Cross-linked Sodium Hyaluronate Powder (2.3Mda) is a cutting-edge chemically modified biomaterial designed for high-demand applications in medical aesthetics and pharmaceuticals. Crafted by covalently bonding linear hyaluronic acid (HA) chains via advanced cross-linking agents, this 2.3Mda HA Powder delivers unparalleled stability, viscoelasticity, and in-vivo retention—addressing the core needs of manufacturers for reliable dermal filler raw materials and medical-grade HA solutions. Unlike unmodified HA, the cross-linked polymer structure resists enzymatic degradation, ensuring long-lasting efficacy in clinical settings. Widely trusted by biotech companies and medical device manufacturers, this product excels as an injectable filler base (for lip augmentation, nasolabial fold correction) and a key component in joint cavity injections, ophthalmic viscosurgical devices, and wound dressings. Every batch adheres to strict international standards, making it a top choice for professionals prioritizing safety and performance.

Test Items | Acceptance Criteria | Test Result |

1. Characters | Whiteor almost white granule, powder or fibrous aggregate | Complied |

2. Identification | ||

A. Identification or IR spectrum | Corresponding to reference spectrum | Complied |

B. Uronic acid reaction | Purple and red color | Complied |

3. Clarity and color of solution | Clear;A600nm≤0.01 | Clear;A600nm:0.006 |

4. pH | 5.0~8.5 | 6.3 |

5. Particle size | D10-D90:100~1200μm, D50: Actual value | 210~781μm 445 μm |

6. Viscoelasticity | Actual value | Elastic modulus: 1101.0 Pa Viscous modulus: 311.8 Pa |

7. Loss on drying | ≤15.0% | 2.1 % |

8. Heavy metals | ≤10 ppm | <10 ppm |

9. Residue on lgnition | ≤18.0 % | 11.4 % |

10.Residual ethanol | ≤0.5 % | 0.3 % |

11.Residual BDDE | ≤50μg/g | Not detected |

12.Assay of Sodium Hyaluronate | 95.0 %~105.0% | 95.8 % |

13.Bacterial Endotoxins | <0.05 EU/mg | <0.05 EU/mg |

14.Total aerobic microbial count | ≤500 cfu/g | <20 cfu/g |

15. Total yeasts and molds count | ≤100 cfu/g | <20 cfu/g |

16. Staphylococcus aureus | Negative | Negative |

17.Escherichia coli | Negative | Negative |

18.Pseudomonas aeruginosa | Negative | Negative |

Exceptional Tissue Compatibility: The cross-linked polymer boasts superior biocompatibility, minimizing adverse reactions in medical applications. It integrates seamlessly with human tissue, making it ideal for injectable medical aesthetics and surgical devices.

Rigorous Safety Compliance: Test results confirm undetectable residual BDDE (a common cross-linking agent impurity), heavy metals <10 ppm, and bacterial endotoxins <0.05 EU/mg. This exceeds global medical standards, ensuring patient safety.

Superior Stability & Viscoelasticity: With an elastic modulus of 1101.0 Pa and viscous modulus of 311.8 Pa, the powder maintains structural integrity in vivo, outperforming non-cross-linked alternatives for long-lasting dermal fillers and joint injections.

Controlled Drug Release Support: In pharmaceutical formulations, the polymer precisely regulates drug release rates, boosting therapeutic efficacy and improving patient experience— a critical advantage for drug sustained-release systems.

Patented Cross-linking Technology: Bouliga’s proprietary process ensures consistent molecular weight (2.3Mda) and cross-linking density, eliminating batch-to-batch variations that plague lower-quality HA powders.

Versatile Application Scope: From skin regeneration materials to ophthalmic devices, this powder adapts to diverse manufacturing needs, reducing the need for multiple raw material suppliers.

Packaging Options: 1kg/bag double aluminum foil bags or vacuum packaging with desiccants (moisture-proof, light-resistant). Custom packaging (5kg/bag, 25kg/drum) available for large orders.

Minimum Order Quantity (MOQ): 1kg (sample orders available for qualification testing).

Lead Time: 3-5 working days for standard orders; 7-10 days for customized packaging.

Transportation: Room temperature shipping via TNT, FedEx, DHL, or EMS. Global distribution network ensures timely delivery to over 50 countries.

Storage Conditions: Sealed, dry, and cool environment (2-25°C), protected from direct sunlight. Shelf life: 24 months when stored as recommended.

Simply mix the Cross-linked Sodium Hyaluronate Powder with purified water (ratio depends on desired viscosity; typical 1-5% w/v). Stir gently at room temperature until fully dissolved—no heating required. The solution forms a smooth, viscoelastic gel ideal for injectable fillers.

Yes. The powder holds code 3913900090 and meets CE, FDA, and ISO 13485 requirements for medical devices and pharmaceutical raw materials. Third-party certification reports are available upon request.

Absolutely. The cross-linked polymer forms a breathable protective film, accelerating wound healing and reducing scar formation— a key benefit for medical wound care materials.

Cross-linked HA offers significantly higher stability, viscoelasticity, and in-vivo retention. Non-cross-linked HA degrades quickly, making it unsuitable for long-lasting applications like dermal fillers or joint injections.

Yes. Our team of biotech experts provides free formulation guidance to help optimize your product’s performance. Contact our technical support team for customized solutions.